DRILLING

Leveraging advanced drilling and machining technologies, we process a wide range of materials, including various resins and soft metals. Without the need for mold fabrication, our multi-spindle drilling system enables simultaneous processing, allowing us to keep costs low and efficiently handle both small and large-scale production.

ROUTING

Our outline machining and countersinking services ensure precise processing to your required specifications. With extensive production capacity, we swiftly accommodate requests for miniaturization and customization. Our state-of-the-art machinery enables high-speed, mass production of intricate shapes.

- ●Key Processing Features

- ・Burr-free and residue-free processing

- ・High-speed mass production of fine outline machining with an accuracy of up to 30µm

- ・Precision countersinking with a mirror finish and precise depth control

- ・Equipped with an optical measurement system for precise dimensional verification

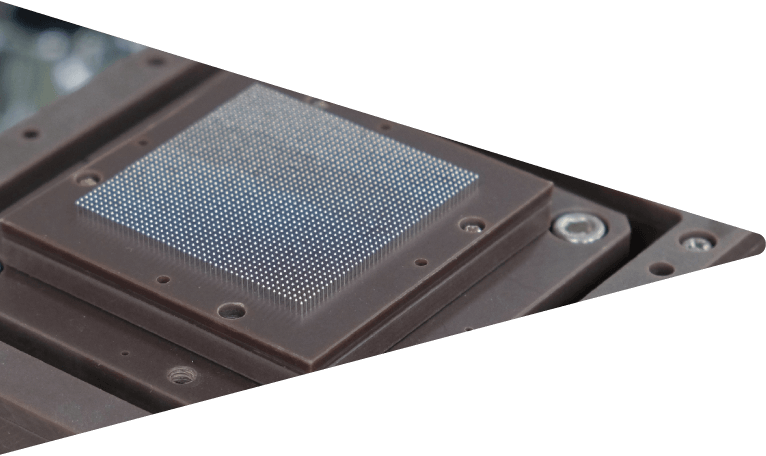

JIG

POINT/ Designed and manufactured to meet the functional requirements of various inspection equipment manufacturers and set manufacturers.

With high-precision hole positioning and high-quality inner walls, our jigs ensure accurate detection of inspection points.

We can design and produce a variety of jigs, including alignment calibration jigs, CSP, BGA, IC, ICT, and FCT jigs, as well as custom precision jigs for specialized applications.

Additionally, by collaborating with our overseas factory in China, we offer cost-saving solutions.

MACINNING

CNC machining utilizes a CNC-controlled automatic tool changing system to perform various processes such as milling, boring, and drilling simultaneously to accommodate diverse processing needs. This system allows us to provide customers with a cost-effective, integrated manufacturing solution using CAD・CAM for complex 3D object processing, eliminating the need for traditional jigs and molds.

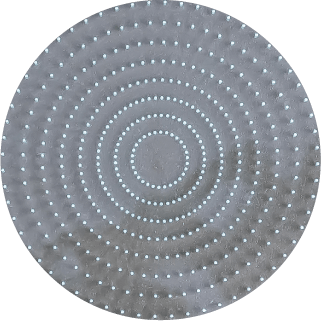

PUNCHING

PRESS

Punching is a fabrication process used for perforating board or sheet materials using dies such as Thomson and Pinnacle dies. Compared to other processing methods, punching is faster and more cost-effective. Holes can be precisely perforated in uniform patterns at a low cost, though it requires an initial investment in the die. Additionally, custom dies can be created to punch holes in various shapes.

LASER

Laser processing utilizes high-energy, highly directional laser beams for precision drilling, cutting, and surface treatment.

It is applicable to cutting, drilling, surface hardening, and engraving for both metallic and non-metallic materials such as wood and rubber.

This non-contact method enables high-precision machining even for delicate materials.

The Value of Hole Processing

Our hole processing technologies will create infinite values and possibilities. Let us introduce various functions that a precise hole processing can bring.

Conductivity

Conductivity

Plating inside the holes enables electrical conductivity between the upper and lower surfaces.

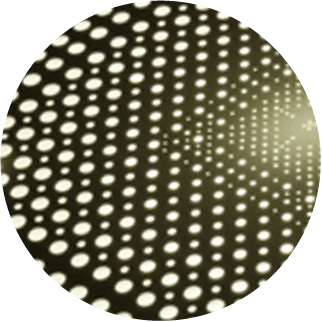

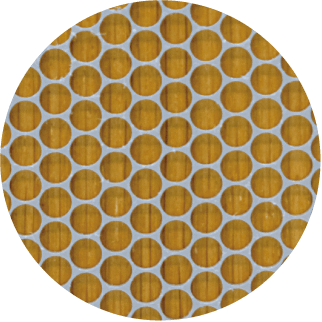

Permeability

Permeability

You can see through the holes. By adjusting the pitch, the amount of transmitted light can be controlled.

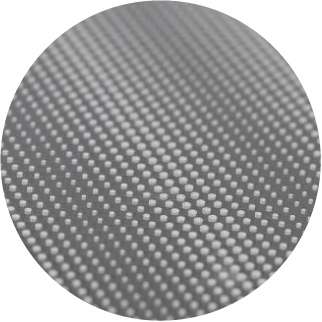

Liquidity

Liquidity

Optimizing hole size and spacing allows liquid and gas to pass through while maintaining material strength.

Lightness

Lightness

In applications where weight reduction is critical, strategically placed holes help reduce overall weight.

Sound absorbency

Sound absorbency

When sound passes through the holes, it creates a sound absorption effect. Optimizing hole arrangement can maximize noise reduction.

Breathable

Breathable

By opening the holes, air can pass through a flat surfaced material. Breathable material has numerous applications across different products.

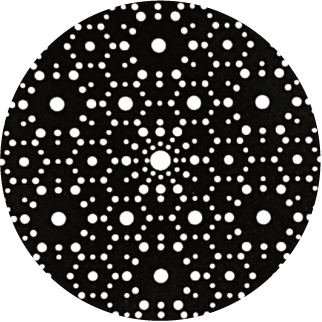

Designability

Designability

High-precision hole processing enables intricate graphic designs.

Heat dissipation

Heat dissipation

Ideal for heat-sensitive applications, perforations facilitate effective heat dissipation.