Widely Used in Automobiles and Aircraft: What is Perforation Processing Applied to Surface Sheets?

1. Introduction

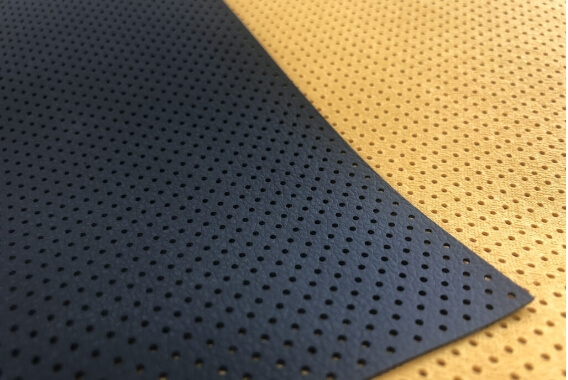

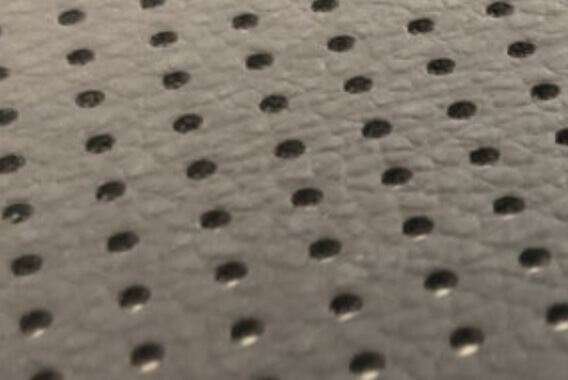

Perforation is a drilling process that creates small, evenly spaced holes in leather (genuine leather¹, synthetic leather², or artificial leather³) to enhance sound absorption and breathability. This process not only preserves the natural warmth and texture of the leather but also improves ventilation, resulting in a softer and more comfortable feel. Additionally, its sound absorption properties contribute to a quieter interior environment, making it a highly valuable material.

※1 Genuine Leather: Natural material derived from animal hides.

※2 Synthetic Leather: A combination of natural material and PVC (polyvinyl chloride) or PU (polyurethane).

※3 Artificial Leather: Made from nylon or polyester fibers combined with PU (polyurethane). Artificial leather does not contain any natural materials but closely resembles genuine leather. It is commonly referred to as "fake leather.

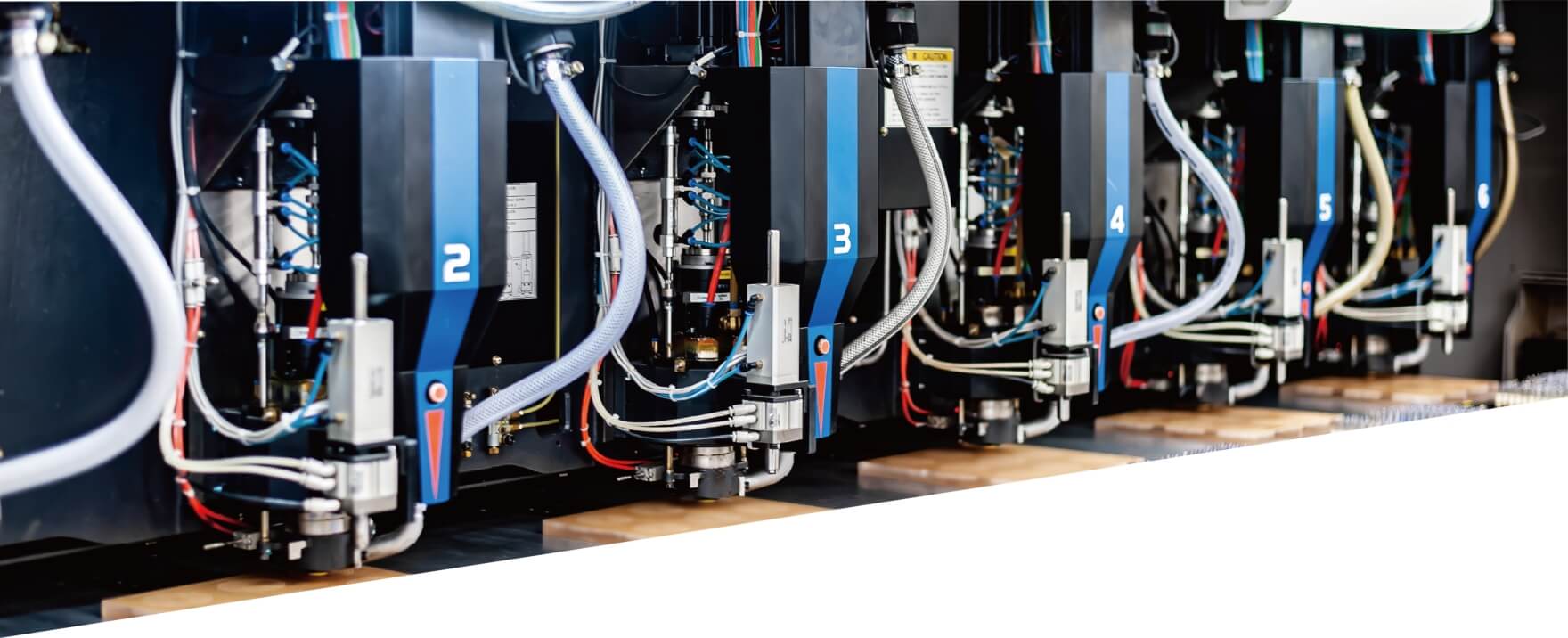

2. About NC Perforation

NC Sangyo’s drilling technology enables ultra-small-diameter hole processing on seat leathers (genuine leather, synthetic leather, artificial leather) and drilling on composite materials with urethane laminates. We manufacture seat perforations featuring diverse designs and functionalities with high quality and a small-lot production system.

2-1. High-Quality Drilling Techniques

Our drilling process ensures clean, burr-free hole creation. With a wide range of drill sizes available, we can produce through-holes, non-through holes, and cutting processes. Additionally, our capability to process holes of varying diameters allows us to create multiple hole sizes within a single sheet, enabling clearer and more intricate designs.

Comparison with Punching Hole Processing:

Punching Holes: This process involves using hollow pins, which can cause fiber clogging inside the pin as the pin diameter decreases. This often results in deformation and poor finish quality.

Drilled Holes: Drilling, on the other hand, minimizes deformation, burrs, or burns, achieving a much cleaner and more aesthetically pleasing finish.

Unlike punching, which requires a fixed hole arrangement, our drilling technology enables flexible hole patterns on a single sheet, making it possible to create complex and diverse design expressions.

2-2. Specifications of NC Perforation

- Hole Diameter: Capable of processing holes from Φ0.4 mm to Φ6.0 mm (in increments of 0.05 mm).

- Sheet Size: Can process sheets up to 530 mm × 680 mm. Larger sizes can also be accommodated upon consultation.

- Punching Limitations: The minimum hole diameter for punching processes is Φ0.8 mm due to pin setup restrictions, with a minimum pitch of 5 mm between holes.

- Efficiency: Our six-axis simultaneous processing and layered processing (depending on material thickness) enable high-efficiency production.

- Composite Materials: Capable of processing on composite materials, including surface materials alone or surface materials combined with urethane laminates.

Cost-Effectiveness: Unlike conventional punching, which requires mold fabrication for each new or modified design, our NC data system eliminates the need for molds, significantly reducing initial costs.

3. eVTOL Aircraft Industry

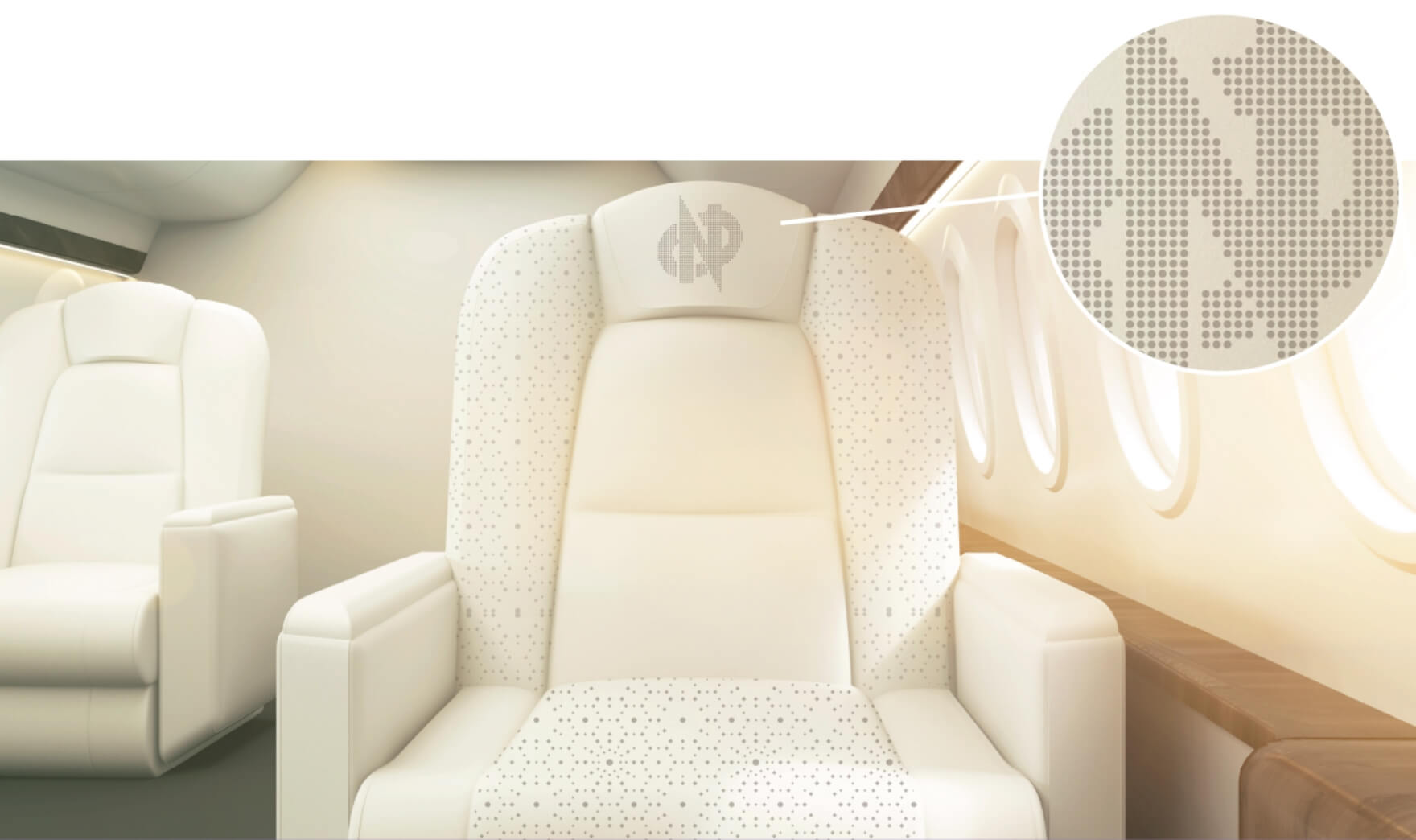

Combining elegance and high performance. As demands for passenger aircraft seats continue to rise, the eVTOL industry is experiencing rapid growth. We support seat design in the aviation industry with advanced technology, including:

Designing and manufacturing first-class seats that seamlessly blend high functionality with luxury.

Applying perforation that enhances both aesthetics and load distribution.

Our expertise ensures the highest standards for aircraft seat manufacturing.

3-1. Small-Lot Production for Luxury Seats such as First Class

We provide perforation for executive cabin seats, including those in first-class and business-class sections of aircraft. With our drilling method, molds are unnecessary, allowing us to deliver high-quality perforation on materials like artificial leather and genuine leather, even for small-lot orders. Additionally, a variety of dot arrangements, including logos and design patterns, can be created.

3-2. Functional Drilling Combined with Sound Absorption Features

We offer drilling that integrates sound absorption effects using high-performance materials with antimicrobial properties, suitable for laminated partitions and similar applications. Complex design patterns can be applied flexibly to meet your creative requirements.

3-3. Customizable Ventilation Holes with Freely Adjustable Diameters for Warm Air

We can add functionality such as ventilation holes for warm air from seat heaters. Hole sizes and combinations are fully customizable, with a minimum diameter of Φ0.4 and a maximum diameter of Φ6.0. The processing size is up to 530 × 680 mm (larger sizes, such as 1000 × 1000 mm, can also be accommodated).

3-4. Anti-Slip Drilling for Control Sticks and Other Grip Surfaces

We can create integrated dot patterns that provide anti-slip functionality for handles, control sticks, and other grip surfaces.

4. Automotive Industry

The advanced technology of NC Perforation is not only used in the aviation industry but also plays a significant role in the automotive industry, particularly in interior seat production.

4-1. Integrated Seat Drilling with Sound Transmission Holes

We offer perforation for eVTOL and automotive seats, with integrated drilling for speaker sound transmission holes.

4-2. Prototype Support for Weight Reduction Studies

We accommodate a wide variety of materials categorized by color and functionality. Drilling enhances weight reduction performance, making it ideal for lightweight design applications. By integrating digital evaluation, we excel in precise prototyping for small-lot production, delivering high-quality results tailored to specific design needs.

5. Customer Feedback

Wide Variety of Design Options

Punching could only process fixed patterns and didn’t allow for multiple designs on a single sheet. With drilling, we were able to use multiple patterns to achieve an innovative design, and we are very satisfied with the results.

Capability to Process Composite Materials

We appreciated your ability to handle not just surface materials but also surface materials combined with urethane laminates.

Hole Diameter and Pitch

With punching, the minimum hole diameter was Φ0.8, and the pitch between holes was limited to 5 mm due to pin setup issues. Drilling achieved much smaller pitches with a remarkably clean finish.

High-Quality Finish

When we switched to your drilling process, we were amazed by the clean results, free from deformation, burrs, or burns.

Efficient Processing

Thanks to six-axis simultaneous processing and the ability to layer materials based on their thickness, the final product was completed much faster than expected.

No Initial Costs

With traditional punching methods, we had to create new molds for every design change, which incurred high costs. By working with your company, only NC data creation or modification was needed, leading to significant cost savings.