Excellent Workability at a Reasonable Price

For high-quality transparent cast sheets, choose NC Acrylic.

1. Introduction

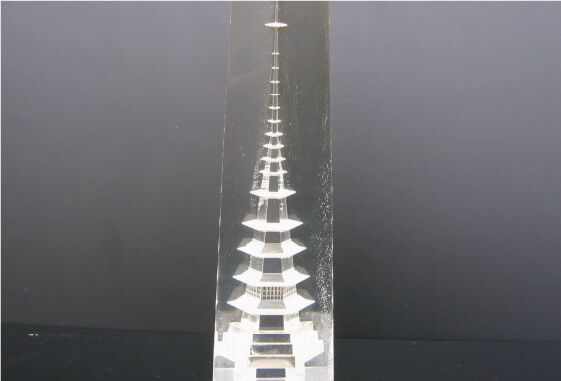

Acrylic sheets (PMMA) are highly transparent and are often referred to as the “Queen of Plastics.” They are widely used in a variety of applications, such as plates for jigs, acrylic fixtures, displays, and aquariums. Additionally, they are commonly utilized in showcases, commemorative trophies, and sound-absorbing panels. Furthermore, acrylic sheets play a significant role in droplet prevention boards and are frequently incorporated into novelty items.

2. About NC Acrylic

NC Acrylic is a transparent cast acrylic sheet designed with a focus on workability and precision.

Among cast methods, it offers:

Superior thickness accuracy

Higher molecular weight, resulting in minimal warping and shrinkage

Dual-sided paper masking for enhanced protection

This makes it an exceptional choice for high-quality acrylic materials.

-

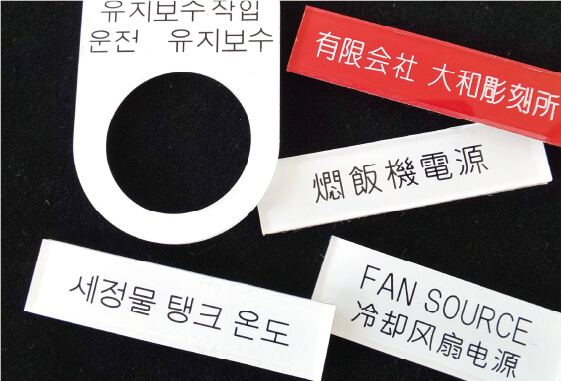

Examples of Engraved Products -

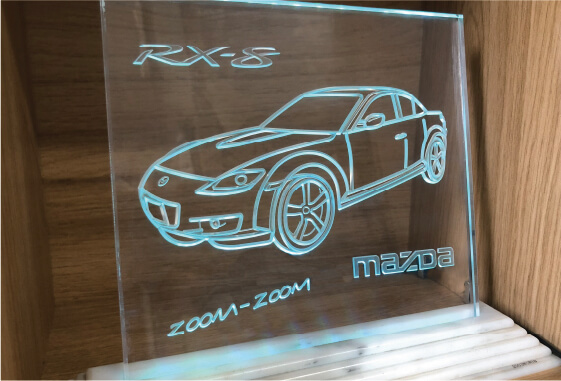

Examples of Commemorative Items -

Examples of Nameplates -

Examples of Display Items -

Examples of Exhibition Fixtures -

Examples of Water Quality Testing Pipes

In-House Developed Sound-Absorbing Droplet Prevention Board

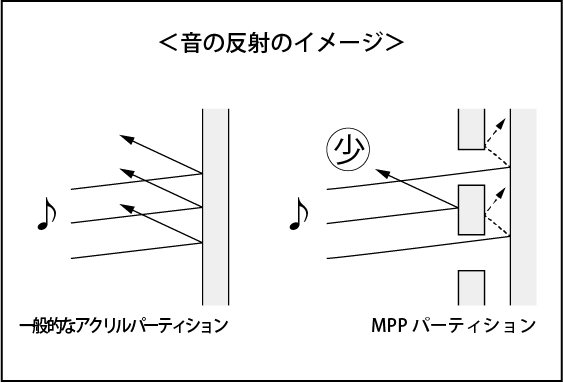

To prevent the spread of new viral infections, partitions have become widely used in stores, facilities, and offices, meeting various demands. However, one common issue is that voices reflecting off partitions can cause discomfort and noise disturbances for those nearby.

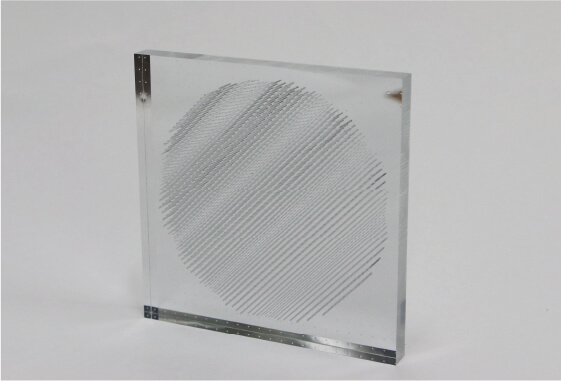

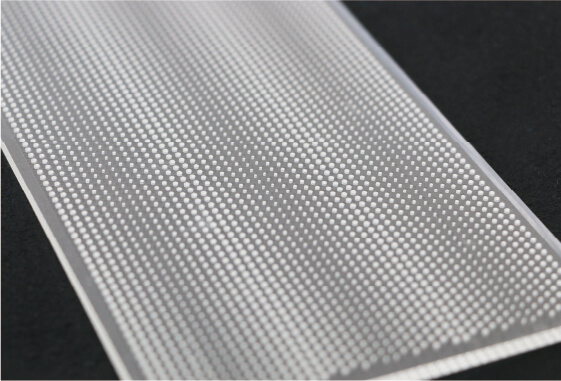

In collaboration with Kobe University, NC Sangyo has developed an original "Sound-Absorbing Partition," featuring a structure with countless small holes designed to absorb sound effectively. This innovative design minimizes sound reflection, helping to create a quieter and more comfortable environment.

-

Examples of Sound-Absorbing Splash Prevention Panels -

Examples of Sound-Absorbing Splash Prevention Panels -

Examples of Partitions

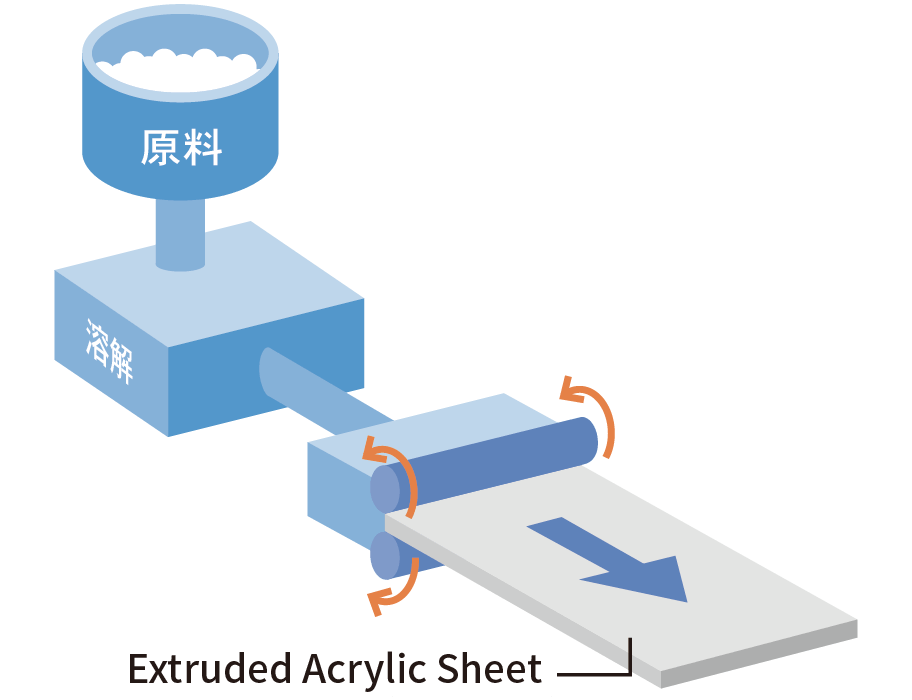

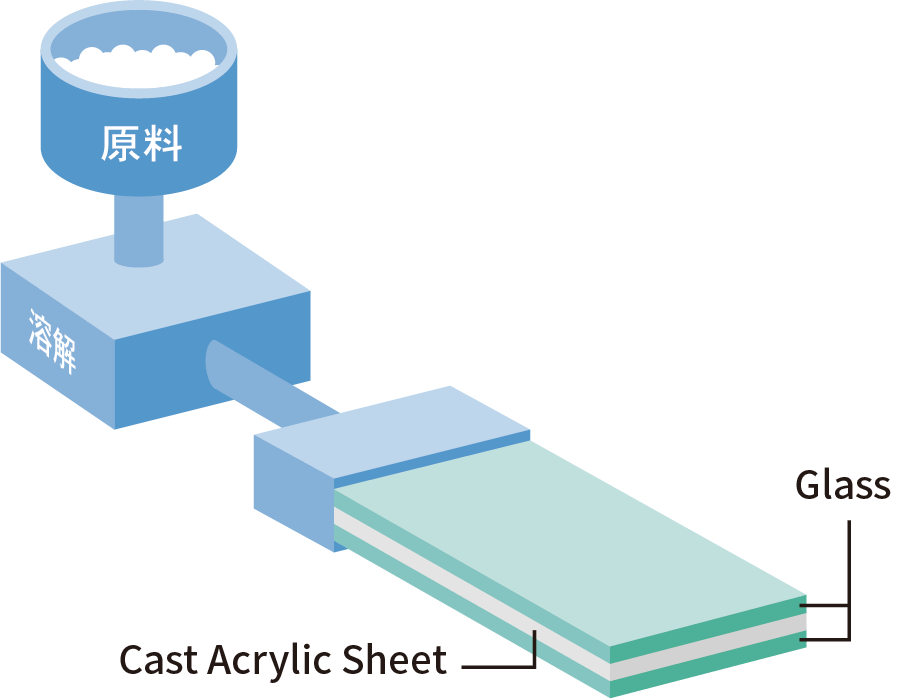

2-1. High-Quality Cast Sheet Method

NC Acrylic utilizes a cast sheet manufacturing method, where raw materials are poured between two glass plates and cured. Compared to extruded sheets, cast sheets have a higher molecular weight, resulting in increased hardness and excellent machinability. Additionally, our proprietary annealing process minimizes warping, making it an ideal material for precision drilling applications, such as jig plates.

For production, we have expanded Japanese casting manufacturing technology to South Korea. With over 30 years of partnership, we have established a strong relationship of trust with our suppliers. Our maximum import volume reaches up to 20 tons per month, handled in container units. Compared to domestically produced cast sheets, NC Acrylic provides a cost-effective alternative while maintaining high quality.

The primary materials used in our production process include extruded sheets, cast sheets, and glass. These are manufactured using two main methods: the Extrusion Method, which is suited for high-speed mass production, and the Cast Sheet Method, which offers superior clarity, durability, and machinability.

2-2. Specifications of NC Acrylic

| Color: | Transparent only |

|---|---|

| Masking: | Paper masking (Poly masking available upon consultation for bulk purchases) |

| Size: | 1000 × 2000 mm (915 × 1830 mm also available as a custom order) |

| Thickness: | 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm, 13 mm, 15 mm, 20 mm Additional services include consultations for scrap material sales. |

Acrylic Processing and Sales Services

Due to overseas production, NC Acrylic offers low-cost pricing and a stable supply of imported acrylic, ensuring short lead times.

We can cut sheets to the specified sizes and provide additional finishing options, including:

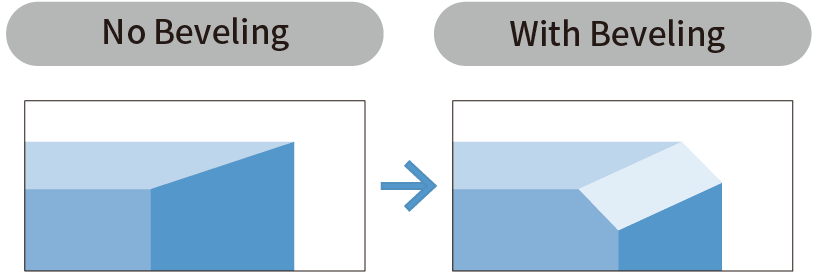

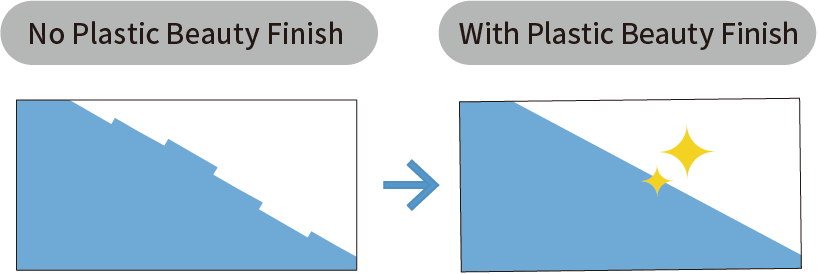

Cut edges only,Transparent gloss finish (Plastic Beauty processing),Beveling

Corner cutting,Our facility is equipped with dedicated hole drilling machines and machining centers, allowing us to accommodate various acrylic processing needs, including bonding, bending, and custom free-cut processing.

- ● Single sheet purchases are available. Please feel free to contact us.

- ● Free shipping: Orders over ¥15,000 qualify for free shipping (standard fee: ¥1,500).

- ● Additional processing options, such as Plastic Beauty cutting, edge finishing, and beveling, are available for an extra charge.

-

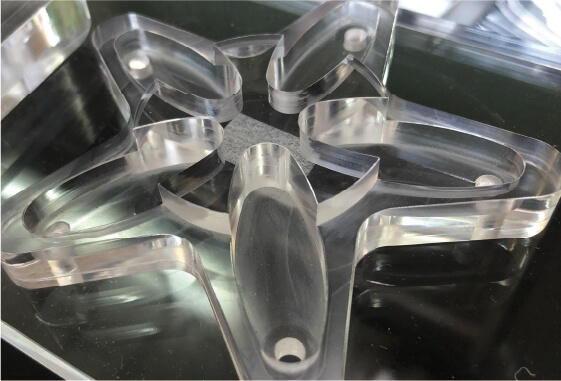

Cutting Examples -

Counterbore Drilling Examples -

Hole Drilling Examples

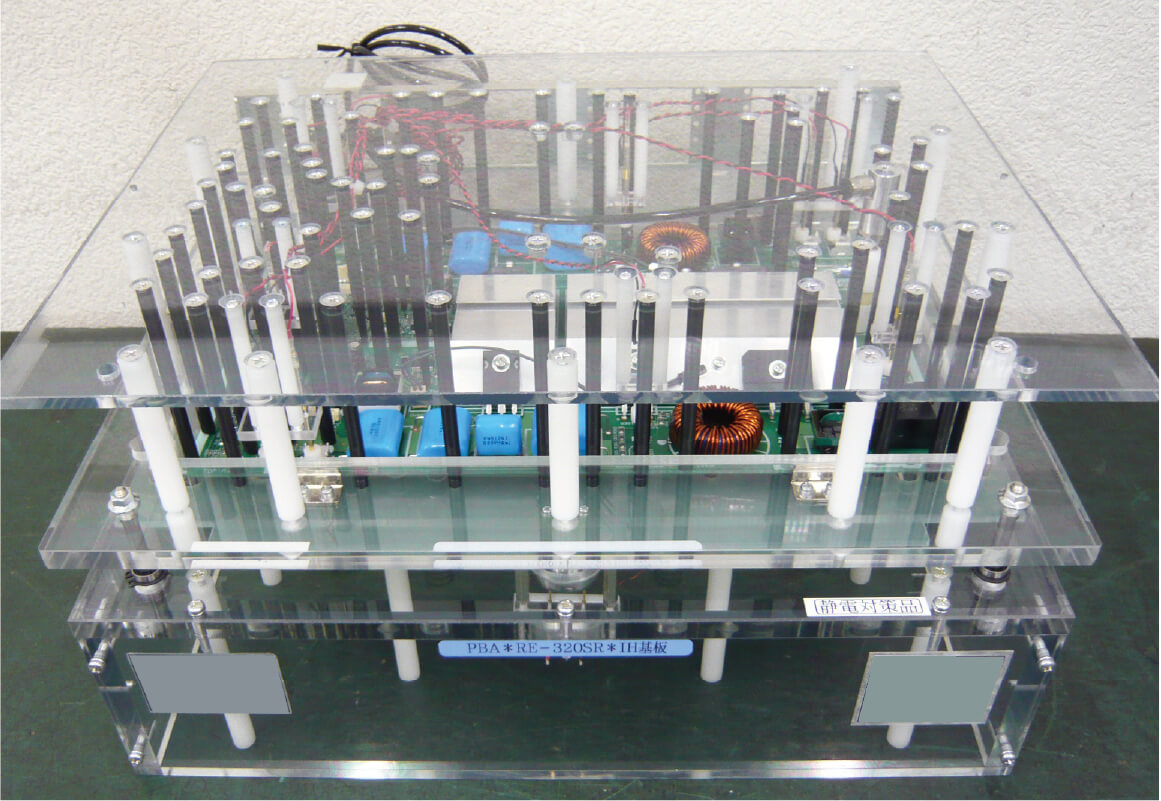

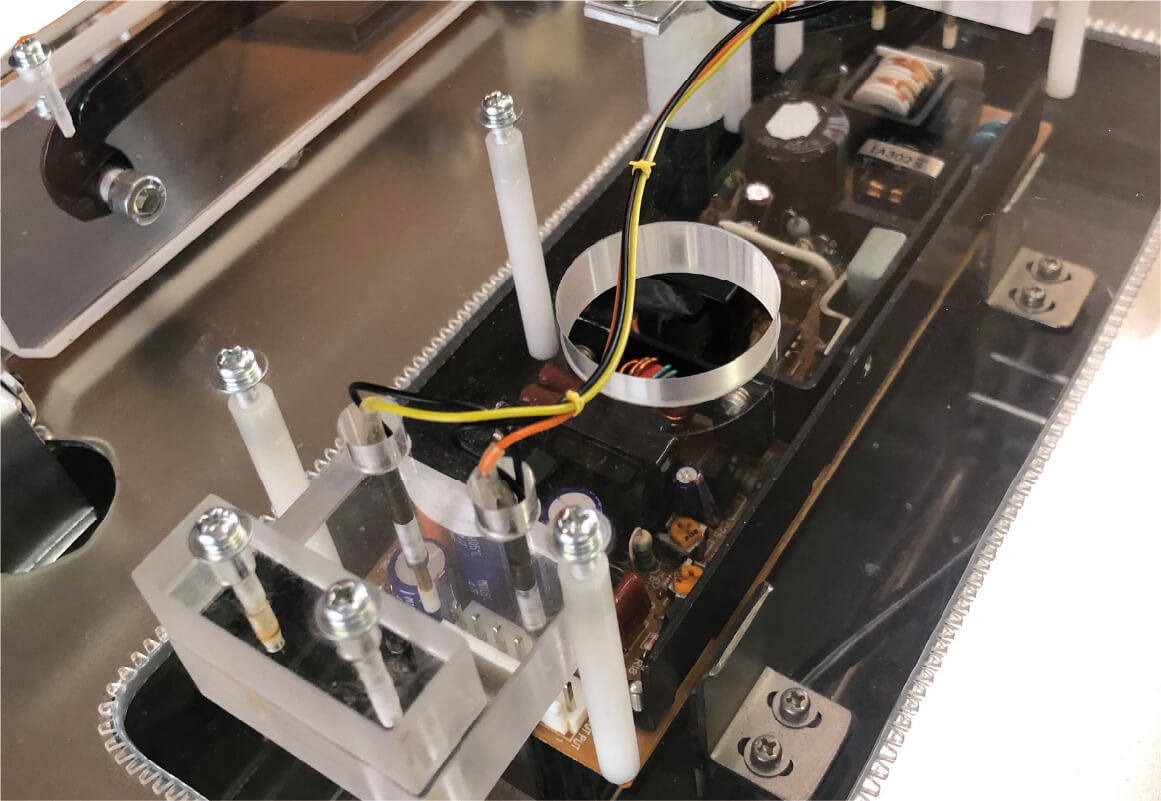

3. Practical Applications of Acrylic Inspection Jigs

Acrylic sheets are widely used for their excellent workability and cost efficiency. Their high transparency makes them particularly suitable for inspection processes, allowing easy verification of product alignment and pin positioning during quality control.

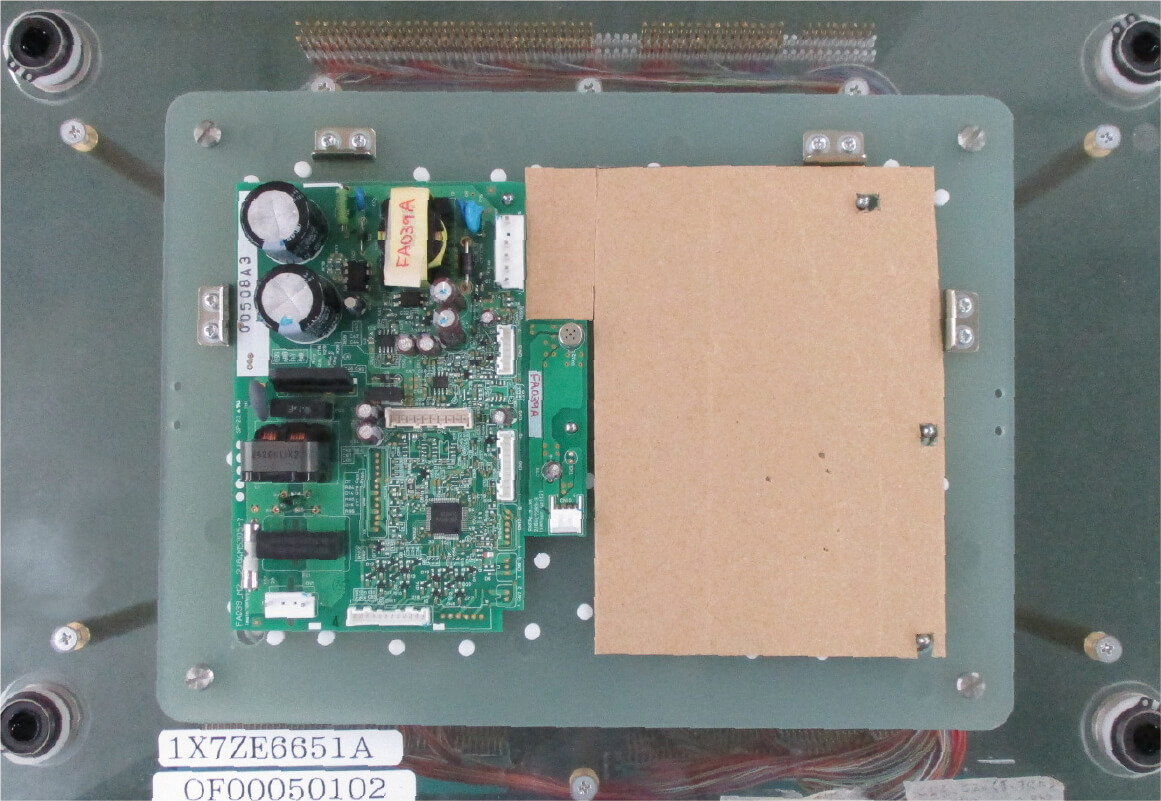

3-1. In-Circuit Tester

An in-circuit tester (ICT) is used for electrical testing of assembled circuit boards. It primarily checks for component failures and issues related to component mounting.

Inspection Focus:Open circuits (disconnected traces),Short circuits(unintended connections),Incorrect component placement

-

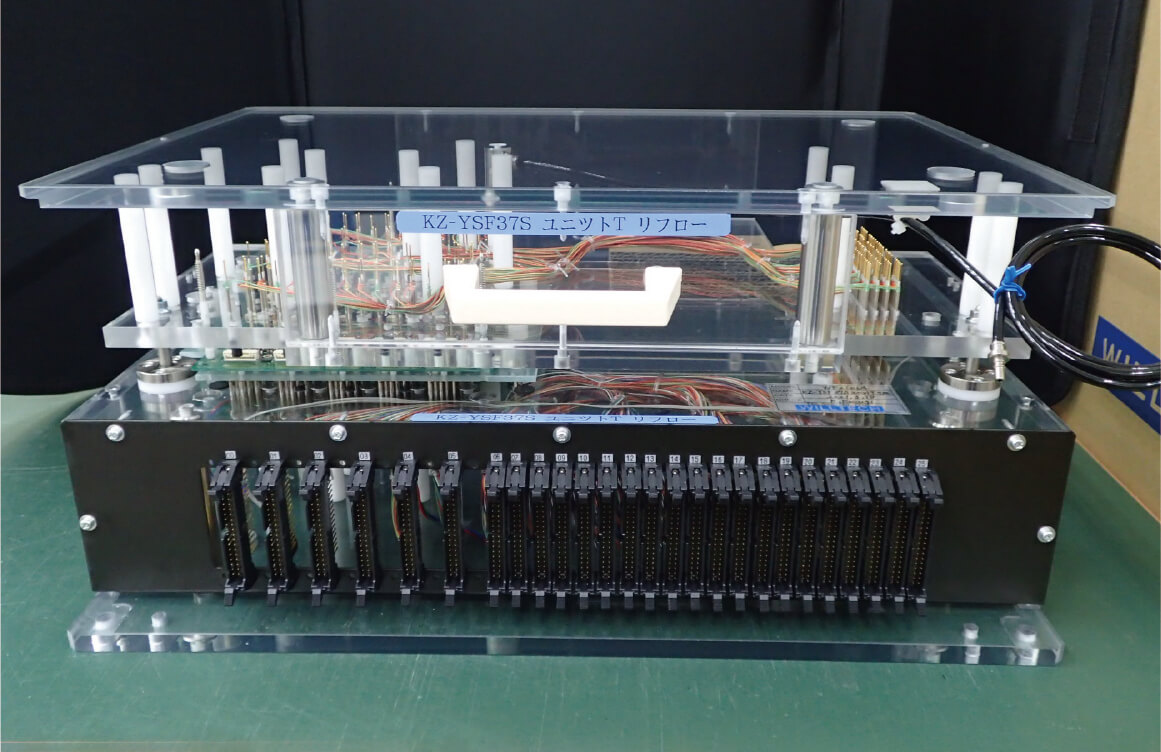

In-Circuit Tester (ICT) -

3-2. Function Tester

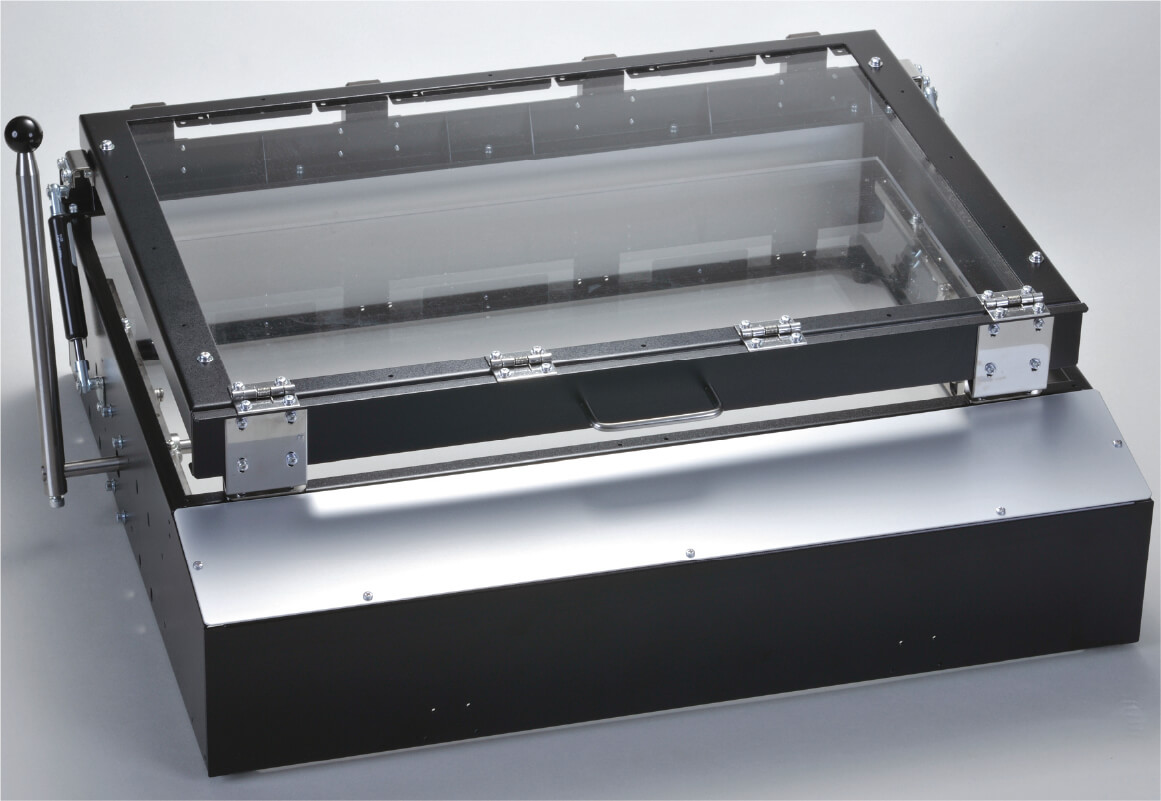

A function tester (FCT) is used for functional testing after electronic components have been mounted. It is generally recommended to first perform an in-circuit test (ICT) to check for structural defects in the assembled board. The function tester then verifies the circuit’s operation under powered conditions.

-

Function Tester (FCT) -

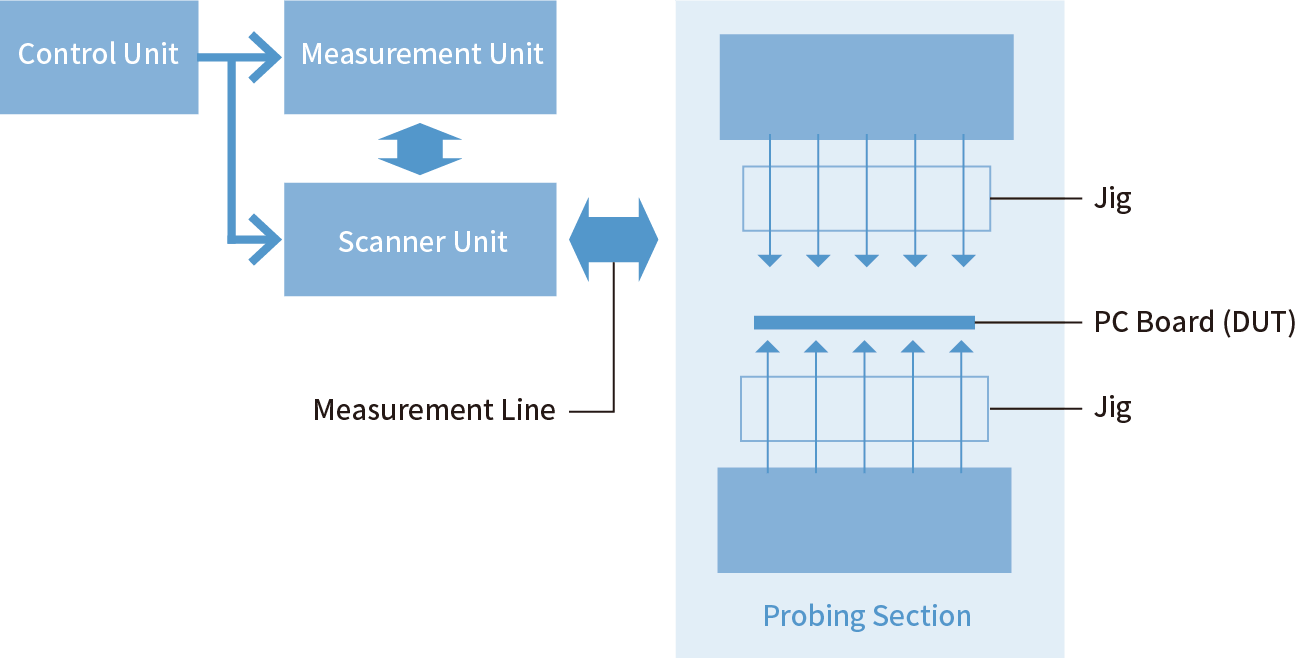

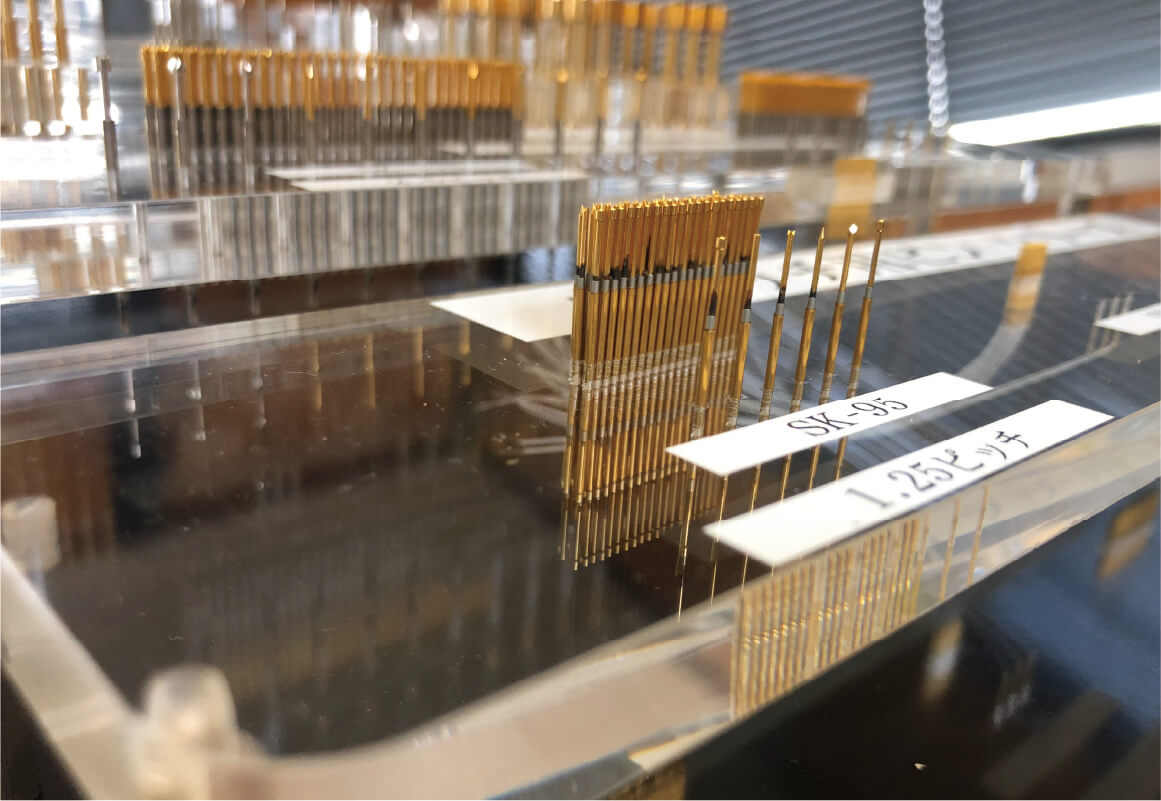

3-3. Jig Method

The jig method uses acrylic sheets embedded with contact probes to create inspection jigs. A press mechanism simultaneously brings all probes into contact with designated test points on the circuit board. While in this state, the measurement lines are switched using a scanner circuit (relay switching circuit) to inspect each electronic component.

Jigs are also referred to as (pin boards) or (fixtures.)

4. About NC Sangyo TPS Group

The TPS (Total Parts Solution) Group was founded with the sale of acrylic sheets and now handles a wide range of resin materials, including thermoplastics, thermosetting plastics, and engineering plastics, as well as acrylic processing and sales.

In addition to resin materials, we source and supply a variety of products and consumables domestically and internationally, addressing customer needs and solving challenges effectively.

-

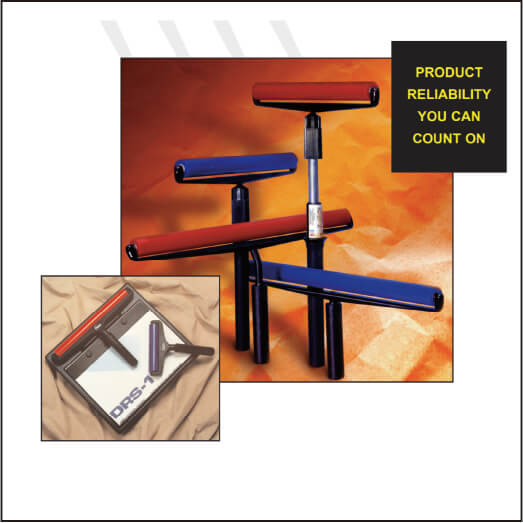

Clean Tape -

Hand Rollers (DRS Series) -

Dust Tack

4-1. Products Handled

- ・NC Acrylic

- ・UV-Transmitting Acrylic

- ・Anti-Static Acrylic (DC Plate)

- ・Unilate

- ・Bakelite

- ・G10 (Glass Epoxy)

- ・POM (Polyoxymethylene)

- ・PPS (Polyphenylene Sulfide)

- ・PET (Polyethylene Terephthalate)

- ・Hand Rollers (for foreign matter removal)

- ・PCR Pads (Transfer Pads)

- ・General Resin and Metal Components

4-2. Distributor Recruitment

We are looking for distributors to sell our products and processed goods.

We provide full support to ensure smooth sales across various industries and regions. Please feel free to contact us for further details.